The era of CNC machining has ushered in a huge range of benefits for machinists, including but not limited to greater productivity, faster manufacturing processes, greater precision, less wasted materials, quicker assembly, and even possibly greater safety.

But it is precision labor, and not free from fault. Very specific end mills and drills must be used for given spotting, cutting, countersinking, threading, and chamfering functions, among others. Using the wrong tools at the wrong speeds can result in unwelcome operational inefficiencies, like chatter.

Luckily, the use of special cutting tools called variable flute end mills may be able to help reduce chatter – here’s a quick primer.

What Is Chatter in CNC Machining?

To put it bluntly, chatter is the occurrence of unwanted vibrations when machining a part. Chatter can occur for many reasons, and it can be either resonant or non-resonant.

Non-resonant chatter can occur when using an unevenly worn cutting tool. This can accelerate the uneven wear or leave a rough, unfinished surface on the material being machined.

Resonant chatter, however, is much more serious and occurs when the natural frequency of the cutting tool is triggered. Achieving the resonant frequency of a cutting tool can occur as a result of improper tool holding or poorly calibrated machine conditions.

Resonant chatter can also occur naturally (since all materials have an innate natural resonant frequency) through no fault of the operator. Regardless, resonant chatter can result in “chatter marks,” a rough finish, or damage to the material you are cutting. It will also shorten tool life, can damage your machine equipment, and even cause the outright failure of the cutting tool, causing it to break.

What Is a Variable Flute End Mill?

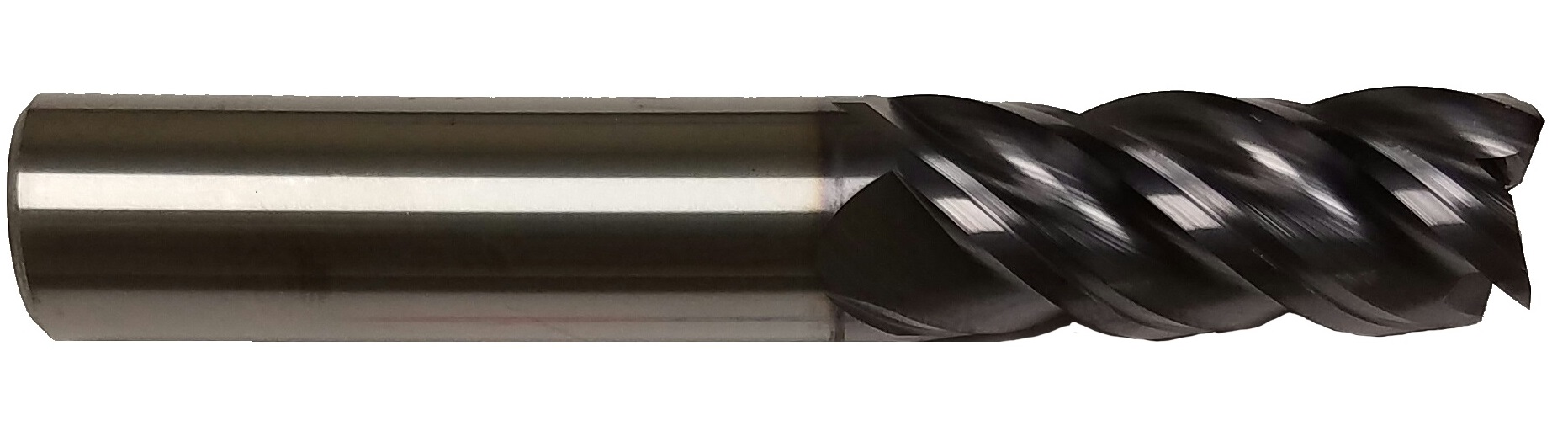

The flutes of an end mill are the raised ridges that bear the cutting teeth. Standard end mills have flutes that are spaced evenly and contain teeth that are also spaced at regular intervals. In variable flute end mills have flutes that are spaced unevenly and also have variable cutting angles along the length of each cutting edge (flute).

It seems to make little sense to make “asymmetric” cutting tools, but there is a big advantage in CNC machining. Variable flute end mills contact the cutting surface at less regular intervals and with variable force, resulting in less consistent vibration during operation. As a result, it is much less likely for a variable flute end mill to attain mechanical resonance, which can damage the end mill, the machine, and the medium.

Because of the lower likelihood of chattering, these high-performance end mills can often be run at faster rates without compromising the life of the tool. The flute design also enables larger chips to be removed, improving chip removal rates when compared to standard end mills.

Where Can You Get High-Quality, Variable Flute End Mills?

Looking for high-quality, solid carbide variable pitch, variable helix, or variable flute end mills that can reduce chatter and operate at increased speeds and feed rates for accelerated material removal?

Visit Online Carbide at OnlineCarbide.com and take a look through their collection or get in touch with them today at Sales@OnlineCarbide.com. They offer fair prices on top quality tools and some orders even qualify for free shipping.

For more information about End Mills For Sale and Drill Mills Please visit: Online Carbide.