There are several steps involved in machining parts in general. Giving your workpiece the desired shape and features might be the actual goal of machining it. But the finishing steps where small details are added, and rough edges are polished is what will ultimately guarantee a job well done.

The most important tool involved in finishing your milled part could easily be your chamfer mill, which makes it a vital addition to every cutter´s arsenal.

Contrary to what many would think, chamfering is much more than just giving your piece an additional luster or making sure your part does not have dangerous edges before handing it to the next guy in the line.

Technically, chamfering could be defined as a process where your mill creates a transitional surface where two planes or sides of a worksheet meet by removing just the right amount of material. Many shops today still dedicate an important part of their time to manual deburring. However, a chamfer mill can help save a lot of time and allow your shop to finish the day with a higher stack of finished parts.

Edges that are 90° degrees or narrower often need to be softened by creating a transitional chamfer. Chamfers are commonly machined at 45° degree angles. However, it all depends on the piece.

But wait, wouldn’t that be the same as beveling?

The first difference between chamfering and beveling is that beveling is a bit more aggressive and removes more material. Chamfering is a process that leaves a clean, crisp edge without removing too much. However, the main difference is that beveling only modifies the meeting angle between two sides. In contrast, chamfering creates an extra side between the two original sides by removing less material.

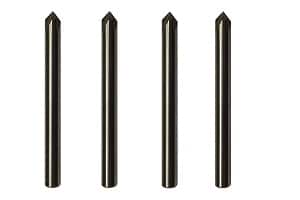

These two processes can be taken care of by a high-quality carbide chamfer mill. Their simple yet ingenious design, allows them to present cutting surfaces in their flutes without going up the shank. They can come in a wide array of angles, each for very specific uses. You might be familiar with the most common varieties of point angles such as 90° and 60°, but specialized chamfer mill manufacturers can offer a more lax range of angles to make sure your tool has the necessary depth for the chamfer cut you need.

I find that carbide chamfer mills are incredibly versatile and efficient, especially when machining harder materials such as steel and cast iron. They have a long lifespan and can take on a lot of wear and tear, and their accuracy and thermal properties make them ideal for side milling notches and engravings without a problem, always leaving polished edges and walls. Carbide chamfer mills also work great on wood as the sharp edges are easy on the grain, leaving incredible finishes in just one pass.

However, you always need to make sure you are working with the best chamfer mills if you want to take advantage of their incredible properties. Visit Online Carbide today and check out their solid selection of carbide chamfer mills and cutting tools. They offer manufacturer-direct prices and shipping options for orders above $250.

For more information about Single Pitch Thread Mills and Variable Flute End Mills Please visit: Online Carbide.